“Panday” is the Filipino word for blacksmith. Given the fact the Filipino martial arts (FMA) collectively, is a weapons oriented system, it would be of great interest to its adherents to examine how the pandays of pre-colonial Philippines worked and produced weapons.

The most renowned Filipino blacksmith of the pre-colonial era is Panday Pira who lived between 1483 to 1576. Panday Pira was a resident of Pampanga though some historical accounts say his roots was in Southern Philippines.

So exemplary was this blacksmith’s skill that the Spaniards later on commissioned him to open their first artillery foundry in the Philippines. Panday Pira was credited for inventing the lantaka, a portable cannon that could be swiveled at any angle during battle. The lantaka could be easily mounted on fortresses and raiding boats like the karakoa.

It is easy to postulate that it was because of Panday Pira that Pampanga became the home of a number of ancient Filipino blacksmithing techniques like “pukpuk” (heat and hammer method) and “pituklip at subu” (folding and forging of hard and soft steel).

While iron was already produced in ancient Philippines, the extraction of metal from the ore by primitive methods is a very tedious process hence it was more practical to trade local forest products for malleable cast iron if available. A regular source of such materials then was the Song merchants who regularly brought Chinese cauldrons to the country.

Besides being skill metallurgists, pre-colonial Filipino blacksmiths, specifically those who specialized in sword making practiced mysticism and spirituality. Using their knowledge of astrology, they observed certain positions of the planets before embarking in their sword making rituals. A fine kris or kampilan may sometimes take years to finish.

On the quality of swords of Southern Philippines, Victor Hurley in his book, Swish of the Kris,” wrote, “Instead of the rude obsidian knives of the Aztecs, the Spaniards at Lamitan found themselves opposed by a flashing kris which was the equal of their Toledo blade.”

An officer of the United States Army’s 22nd Infantry Division, Major O. J. Sweet, during the American colonization of the Philippines described Philippine blades with the following words, “The kris may be of any length and two or three inches wide. All of the knives, no matter what shape, are encased in wooden scabbards, and have a keenness of edge equaling that of a Damascus blade.”

During the Philippine-American war, there were accounts stating of how a Mindanao kris could cut through the barrel of a Springfield rifle.

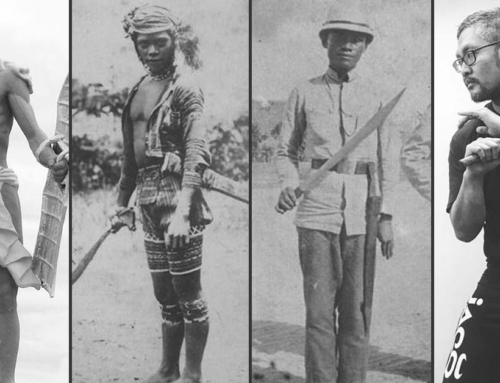

William Henry Scott, offers a more detailed description of the blades produced in the Visayas and Mindanao, in his book “Barangay: Sixteenth Century Philippine Culture, he wrote, “There were two kinds of swords – kris (Visayan kalis) and kampilan, both words of Malay origin.

The kris was a long double-edged blade (modern specimens run to 60 to 70 centimeters), either straight or wavy but characterized by an asymmetrical hornlike flare at the hilt end, called kalaw-kalaw after the kalaw hornbill. The wavy kris was called kiwo-kiwo, and so was an astute, devious man whose movement could not be predicted.

Hilts were carved of any solid material – hardwood, bone, antler, even shell – and great datu warriors had them of solid gold or encrusted with precious stones. Blades were forged from layers of different grade of steel, which gave them a veined or mottled surface – damascened or “watered.”

Scott in his book expounds on the unique position of pandays in pre-colonial Philippine society, he says, “Blacksmiths were panday – or, more accurately, panday sa puthaw, workers in iron, to distinguish them from other craftsmen like goldsmiths, master carpenters, and boat builders, all of whom are called panday. Smithing was considered the noblest profession, probably because only the wealthiest datus had the means to import the raw material.

If they were indeed the ultimate source of all metal tools, including the swidden farmers’ bolos, they would have exercised effective control over Visayan means of production. As Father Alcina (1668a, 3:105) said, “it is certain that no profession among Visayans is more profitable than this, and so it is the most honored and esteemed among them, since the greatest chiefs are the best iron-workers.”

The common tools of the pre-colonial panday were the landasan [anvil], palo [two-handed stone maul], stone hammer [palo-palo], a pair of tongs [kipit], and an array of bolos for cutting the smoldering metal. A panday usually has in his employ an apprentice called “masaop” who mans the hasohas [furnace].

On the kind of works commissioned to a panday in those days, Scott wrote, “The most important tool manufactured, repaired, or retempered by the blacksmith was the bolo. Dohong or dayopak was the ordinary one; tuwad, a heavier one for woodcutting; bako or bantok, one with a curved blade for weeding or cultivating; and pisaw, one with a short blade and long handle to be pressed under the arm or against the ground with the foot to leave both hands free for stripping rattan.

The blade had a tang for hafting into the wooden handle, and was held firm with resinous sap and a ring of rattan or metal. The head of the ax (wasay) was also hafted into the handle; it was only about two fingers wide and could be rotated a quarter turn to be used as an adze.”

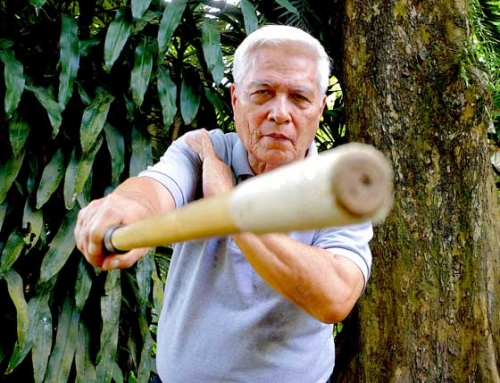

Traditional blacksmithing is still alive in the Philippines today particularly in the countryside. Their earnings usually comes from people who want a custom made bolo or farmers who want their ploughs hammered back into shape as well as the sales of swords and tools they have made.